How to Maintain Accuracy for Non-Contact Infrared Thermometers in Fever Detection Systems

COVID-19 Temperature Screening Processes Could Stick Around

North American sales of non-contact infrared thermometers made a massive jump in 2020 due to the COVID-19 pandemic. Schools, event venues, airports, hospitals, and many other facilities relied on non-contact thermometers as part of their screening process. With a large investment made in infrared thermometers during the pandemic, maintaining the thermometer’s accuracy became an essential component for many facilities.

As fall and winter approach, so does the cold and flu season. Many facilities are making non-contact temperature measurement a mainstay in their entry processes for the long haul, not just for the COVID-19 pandemic. Because of this, investing in an accurate thermometer calibration source that can be used in the field is increasingly important for facilities that screen many people throughout the day like medical centers or schools.

Blackbody Calibrators Keep Non-Contact Infrared Thermometers Accurate

Blackbody sources are commonly used to calibrate infrared thermometers due to their high emissivity. This ensures less heat radiation and the likelihood of radiation interference from the ambient temperature. Blackbody calibrators range in size: larger for fixed use like in laboratories with a need for higher temperature ranges, or smaller for in-the-field use like airports with a need to measure skin temperature. The Isotech 989 Blackbody Calibrator is an example of a smaller-sized blackbody source that ensures infrared thermometers maintain their accuracy for fever detection. With ¼” - 20 UNC thread for standard tripods and the ability to be used horizontally or vertically, the Isotech 989 is used in many different facilities.

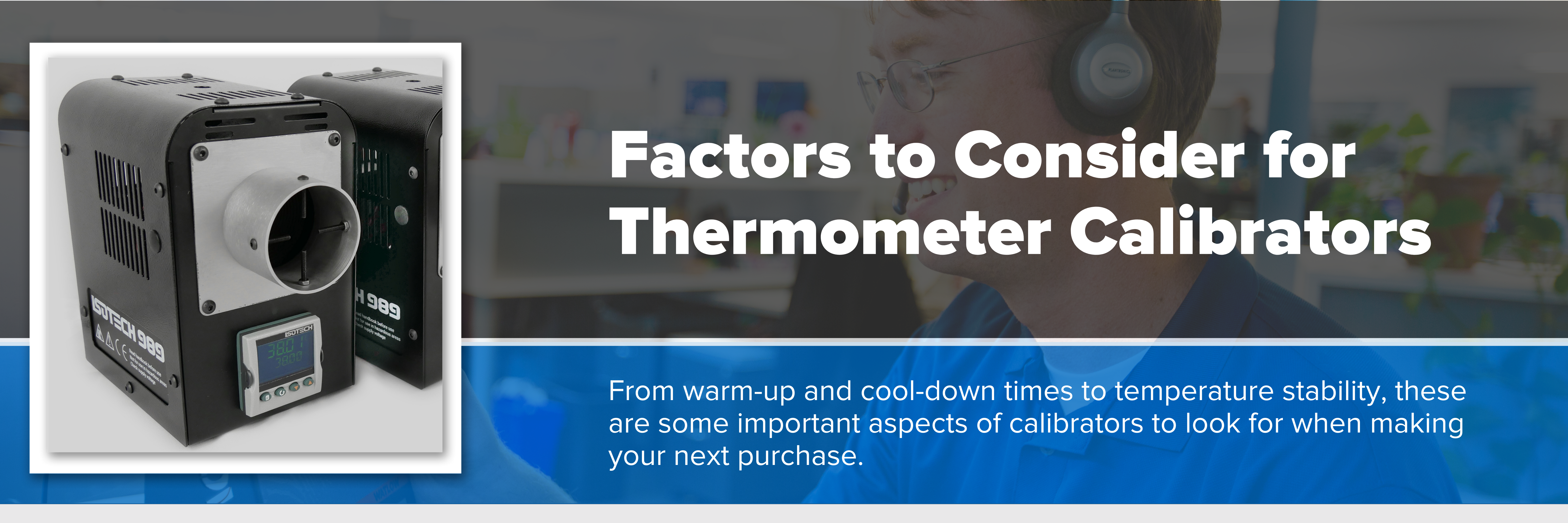

Important Factors to Consider for Thermometer Calibrators

In addition to the influence of ambient temperature, the amount of time it takes a calibrator to warm up or cool down can help reduce process downtime for fever detection systems. The Isotech 989, for example, has an internal solid-state thermoelectric heat pump that heats from 20 to 50 degrees Celsius in about two minutes and cools from 50 to 20 degrees in about five minutes. The heat pump for the 989 Blackbody enables quick cool-down times also allows it to maintain body temperature in high ambient temperatures. If your fever screening process involves high ambient temperatures, you will need a reliable calibrator that isn’t a heat-only system.

The temperature stability of blackbody calibrators ensures the accuracy of the whole system. The Isotech 989 has metrology-grade stability: less than 0.005 degrees Celsius for the short-term range and less than 0.05 degrees Celsius for the 48-hour range. Other important features to look for in a temperature calibrator include the readability of the display, the ability to lock the working temperature for tamper-proof operation, and whether or not there are PC interfaces that allow for remote temperature control and monitoring.

Still Need Help? Call an Engineer Today

The Isotech 989 Blackbody Calibrator is an evolution of the Isotech 988, which was created to aid in the SARS outbreak of the early 2000s. You can learn about the different configurations and accessories that are available for the 989 by visiting the product page.

If this post still leaves you wondering what type of industrial instrumentation would work best for your application, our engineers would be happy to help you. Give them a call at 1-800-884-4967. Or, you can shop for a wide range of industrial instrumentation from top brands and even configure your product online. We offer free lifetime tech support with every product sold.